Our modern, in-house laboratory regularly tests samples taken during each stage of the procurement and production process. We also offer used oil analysis and engine performance tracking, as part of an overall customer service that provides a complete overview of the physical and chemical characteristics of the lubricants being used and recommends specific lubricants for specific tasks.

Cost effective predictive technology

Equipment and lubricant condition is monitored

Experienced, accessible staff provide useful data interpretations & recommendations on every report

Customers can obtain quick accurate and concisely reported interpretation of data. Recommended actions are included with every sample submitted

Most Results within 24-48 Hours

ISO/IEC 17025:2017 Accredited

(TL-1077)

We can offer Lab testing for 3rd Parties

Our modern, in-house laboratory regularly tests samples taken during each stage of the procurement and production process. We also offer used oil analysis and engine performance tracking, as part of an overall customer service that provides a complete overview of the physical and chemical characteristics of the lubricants being used and recommends specific lubricants for specific tasks.

SHARLU provides an experienced, quality-oriented and cost-effective solution to Customers’ oil analysis needs. The full service in-house laboratory provides a wide range of tests on oil, grease, coolants, fuel, and transformer oil.

- Most Results within 24-48 Hours.

- Equipment and lubricant condition is monitored.

- Experienced, accessible staff provide useful data interpretations & recommendations on every report.

- Cost effective predictive technology.

- Customers can obtain quick accurate and concisely reported interpretation of data. Recommended actions are included with every sample submitted.

Turnaround time at SHARLU is critical and watched closely by management as a measure of efficiency.

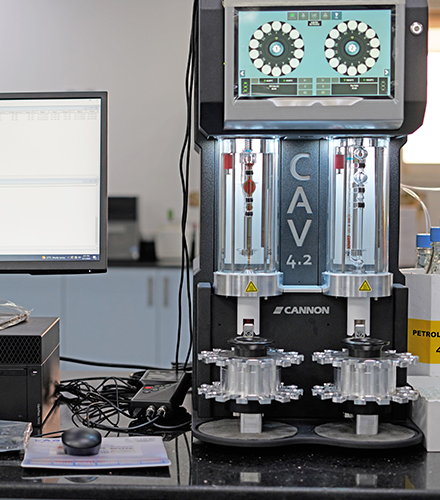

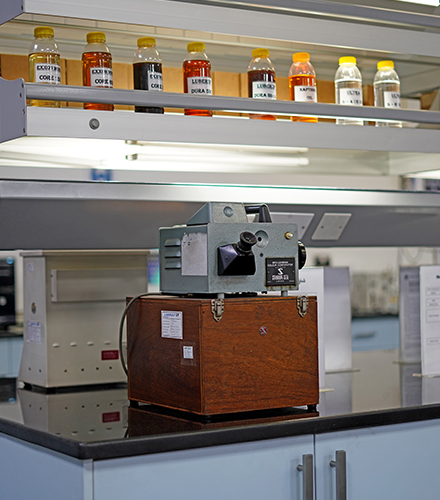

The Laboratory is fully equipped with the most modern equipment such as:

- Cannon Automatic Viscometer – CAV 2000

- Perkin Elmer Optima 2000 – Elemental Analysis (ICP)

- Perkin Elmer Atomic Absorption Spectrophotometer

- Perkin Elmer Infra – Red Spectrophotometer (FTIR)

- Foam Tests

- Demulsification

- TAN / TBN

- Flash Point

- Pour Point

- Sulphated Ash

- Cannon Cold Cranking Simulator (CCS)

Technology

We use the latest oil technology in oil analysis and testing equipment and have a team of fully qualified chemists to provide clients with accurate and prompt sampling analysis and tracking reports

Test Performed [Engine Oil Analysis]

- Color

- Water Content

- Specific Gravity

- Kinematic Viscosity @ 100°C, cST

- Kinematic Viscosity @ 40°C, cST

- Viscosity Index

- TBN, mg KOH/g

- TAN, mg KOH/g

- Flash Point °C

- Pour Point °C

- Sulphated Ash, WT%

- FOAM, ml

- Demulsification, min.

- Wear Metails, ppm

- (Fe,Cu,Ca,Pb,Zn,Cr,Al,Si)

- FTIR

- Penetration, dmm

- Dropping Point, °C

Test Performed [Engine Oil Analysis]

- Color

- Density, Specific Gravity

- Kinematic Viscosity @100°C, 40°C

- TBN (Total Base Number) mgKOH/g

- Flash Point (COC)

- Flash Point (PMCC)

- MRV (Determination of Yield Stress and Apparent Viscosity)

- CCS (Determination of Apparent Viscosity)

- ICP (Determination of Additive Metals, Used Oil Wear Metals)

- N (Determination of Nitrogen Contents in Lubricants, Petroleum Products)

- HTHS (Determination of Apparent Viscosity at High Temperature and High Shear Rate)

- Pour Point

- FTIR

- NOACK Volatility

- Water Contents

- Foaming Tendency, Stability

- Demulsibility, Water Separability

- Brookfield

- Copper Corrosion

- Sulfur Contents